Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

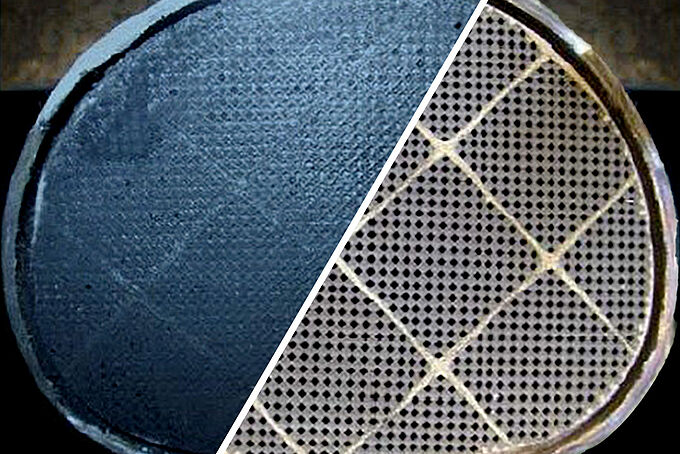

The DPF filter traps soot and ash particles created during diesel combustion. Over time its structure becomes clogged, which leads to power loss, higher fuel consumption, and the DPF warning light. The good news is that in most cases the filter can be cleaned effectively without replacement. In this guide, we show step by step how to clean a DPF filter and what a professional 2HYDRO regeneration process looks like.

The filter needs cleaning when it can no longer complete regeneration on the road and the differential pressure indicates restricted flow. Typical symptoms include:

Depending on how clogged it is, the filter can be partially cleaned DIY or sent for professional cleaning that restores full flow.

There are four main methods for cleaning a diesel particulate filter. Each has its place and effectiveness depending on the filter’s condition:

This process is initiated by the engine ECU. It requires a longer drive at steady RPM (about 2000–2500 rpm) so exhaust temperature exceeds 600°C. Soot then burns off. Effective only with mild clogging.

In a workshop the technician can trigger burn-off with a service computer. This “service regen” helps with moderate contamination, but it does not remove ash and mineral deposits.

A chemical agent is introduced into the filter channels to dissolve soot. After application you start the engine and perform a regeneration drive. It’s a stopgap only—doesn’t clean the entire filter but can restore flow in light clogging.

The most thorough method, performed in specialist shops. The filter is flushed with pressurized water from both sides of the channels, removing not only soot but also ash. Professional equipment such as the MDM-1B machine with 2HYDRO combines two-sided flushing, flow measurement, and drying in one work cycle.

If the filter isn’t heavily clogged, you can try initial DIY cleaning:

If the filter remains clogged, don’t keep experimenting with more chemicals. Excess product can damage sensors and the catalyst. The best option then is professional hydrodynamic cleaning.

In professional shops, cleaning is carried out on specialized equipment. One example is the MDM-1B – a Polish machine for regenerating DPF, FAP and SCR filters using the patented 2HYDRO technology. The process includes three stages:

The full cycle takes about 30–45 minutes, and the filter regains up to 98% of its original flow capacity. The 2HYDRO technology used in the MDM-1B employs a closed water circuit and precise flow control, making the process eco-friendly and safe for the ceramic substrate.

After 2HYDRO cleaning the filter regains full flow, but maintaining the effect depends on driving style and engine condition. Proper use ensures you won’t need regeneration again for a long time.

Cleaning a DPF filter is an effective way to restore engine performance without costly replacement. Depending on contamination level, you can use active regeneration, chemical cleaning, or professional hydrodynamic washing. In shops using MDM-1B 2HYDRO technology, the process is fully controlled and brings the filter close to factory condition. It’s a solution that combines effectiveness, precision, and safety—for both the vehicle and the environment.